How to Measure Pallet Racking: A Comprehensive Guide

When communicating with a supplier about the configuration of a pallet racking system, it can be challenging to grasp the precise details, especially if you're unfamiliar with standard measurements and terminology. At Platinum Storage Solution, our team is dedicated to explaining and guiding you through the process. In this blog post, we provide a comprehensive guide to the fundamental standards for measuring pallet racking.

Measuring Racking Beam Dimension

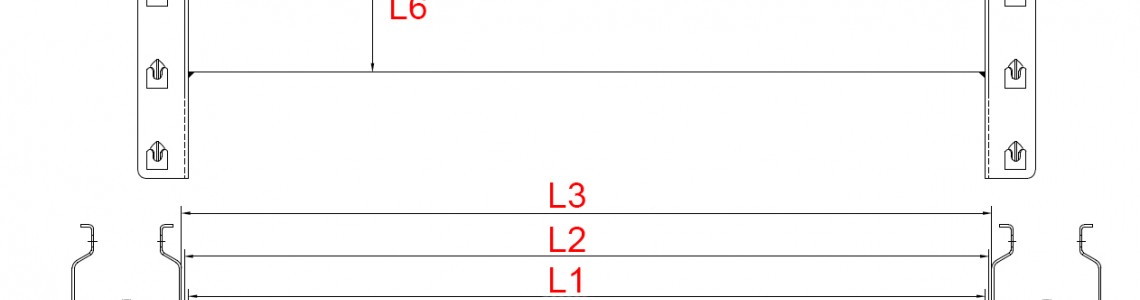

The market offers a wide range of pallet racking sizes, the most important thing is the length. With the most common being a "standard" 2.7m beam designed to accommodate two pallets. However, the length of such beams can vary, ranging from 2700mm, 2740mm, to 2743mm. To accurately measure the beam length, refer to the image below, ensuring that you use millimeters instead of centimeters.

If you look at the diagram below. L1 is the length that refers to the beam length, it is also called "Tube Length" or "Clear Entry Length"

L6 is the side width of the racking beam

L7 is the top width of the racking beam

Measuring Racking Frame Pitch

At Platinum Storage Solution, we prioritize your understanding and satisfaction. With our expertise, we ensure that you're equipped with the knowledge required to navigate pallet racking measurements effectively.

Leave a Comment